Understanding Differential Air Pressure Sensors and Their Applications

- tass peters

- Dec 12, 2025

- 3 min read

Differential air pressure sensors are essential tools in many industries. They monitor pressure changes and provide data critical for various applications. By measuring the pressure difference between two points, these sensors help maintain system efficiency and safety. In this post, we will discuss what differential air pressure sensors are, how they work, and where they are applied.

What is a Differential Air Pressure Sensor?

A differential air pressure sensor is a device designed to measure the difference in pressure between two locations. For instance, in a water filtration system, pressures before and after the filter play a crucial role in indicating the system's health. For example, if the raw water pressure (before the filter) is typically around 50 psi (pounds per square inch) and the filtered water pressure drops to 30 psi, this drop can signal a clog or malfunction. Monitoring these changes is vital for maintaining the system's efficiency and water quality.

How Do Differential Air Pressure Sensors Work?

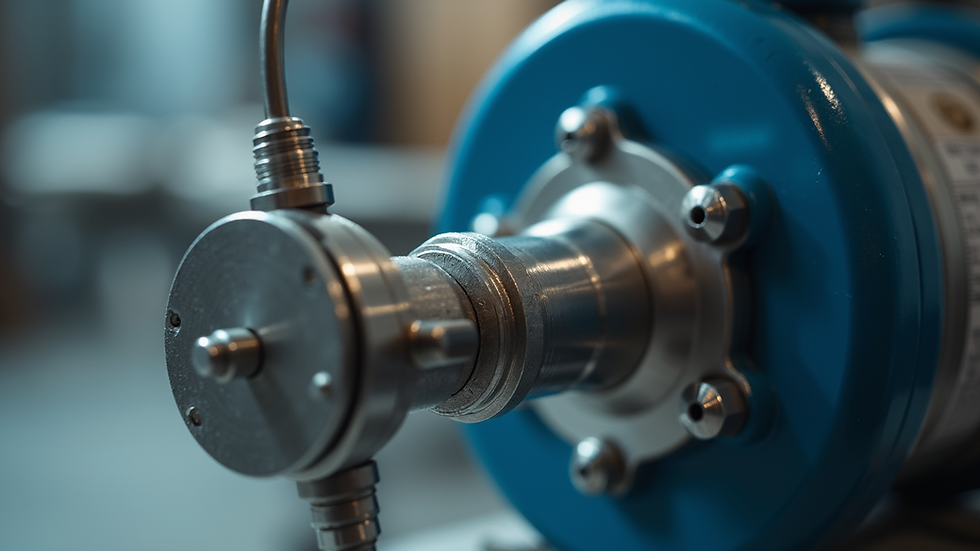

The operation of a differential air pressure sensor relies on key components. A stainless steel diaphragm separates the positive and negative pressure ends. This diaphragm contacts chemically aggressive fluids without failing. The sensor measures differential pressure and transmits this data to a silicon wafer through a filled isolation diaphragm. When a pressure difference occurs, it generates an electrical signal in milliampere levels.

After the electrical signal is created, it goes to a pressure-sensitive sensor connected to a circuit board. The signal is then adjusted for temperature changes to ensure accuracy. The silicon readings are converted to electric signals, processed through a Wheatstone bridge, and analyzed by an electronic board. This process allows for precise, real-time monitoring of pressure differences.

Limitations of Differential Air Pressure Sensors

While these sensors are effective, they do have some limitations. The milliampere signal generated is not suitable for long-distance transmission. Additionally, placing these sensors near strong electromagnetic interference can lead to inaccurate readings, limiting their installation options. Understanding these limitations is vital to ensure optimal performance and accurate data collection.

Applications of Differential Air Pressure Sensors

Differential air pressure sensors find a diverse range of applications across various industries. Here are some specific examples:

1. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, differential pressure sensors monitor airflow. For instance, sensors check the pressure difference between supply ducts and return ducts. If the pressure difference deviates by more than 15%, it can indicate a blockage or malfunction, allowing for timely maintenance. This helps improve energy efficiency and enhances indoor air quality.

2. Water Treatment

As noted, these sensors play a crucial role in water treatment. They monitor pressure differences before and after filtration, supporting operators in detecting issues easily. If the pressure difference exceeds 10 psi, it might signal a clog in the filter. Timely detection helps maintain water quality and ensures the smooth operation of the system.

3. Clean Rooms

In environments like clean rooms, maintaining specific pressure differentials is essential to minimize contamination risks. Differential sensors monitor and control the pressure between clean rooms and surrounding areas. If one area experiences a pressure drop of more than 5 Pascal, contaminants can enter, disrupting the controlled environment.

4. Industrial Processes

Many industrial processes require precise pressure monitoring. Differential pressure sensors are used to track pressure in pipelines, tanks, and reactors. For example, if a tank experiences a sudden pressure change of more than 20 psi, it could indicate a potential failure. Monitoring these pressures helps ensure safe and efficient operations.

Choosing the Right Differential Air Pressure Sensor

When selecting a differential air pressure sensor, consider these factors:

1. Measurement Range

Ensure that the sensor's measurement range matches your specific application. Some sensors are designed for low-pressure systems, while others handle high-pressure environments.

2. Accuracy

Look for sensors with high accuracy ratings. A sensor that achieves accuracy levels of ±1% of full scale will provide you with reliable measurements.

3. Environmental Compatibility

Check the environmental conditions for the sensor's location. Some sensors are robust enough for harsh conditions while others may be sensitive to extreme temperatures or corrosive environments.

4. Output Signal

Different sensors produce various output signals, whether analog or digital. Choose a sensor that integrates well with your existing systems and meets your data transmission requirements.

Final Thoughts on Differential Air Pressure Sensors

Differential air pressure sensors are crucial for many industries, delivering vital data for monitoring and controlling pressure differences. By detecting changes in pressure, they can prevent system failures, boost efficiency, and ensure safety. Understanding how these sensors operate and their practical applications empowers businesses to make informed choices about their implementation.

As technology advances, the uses of differential air pressure sensors will likely expand, becoming even more integral to modern industrial processes. From HVAC systems to water treatment facilities, these sensors will continue to play a key role in achieving optimal performance and safety.