Smarter Maintenance Starts with Smarter Monitoring - Remote Monitoring Solutions

- ProSense

- Jul 17

- 2 min read

Monnit Remote Monitoring Solutions – Powered by ProSense

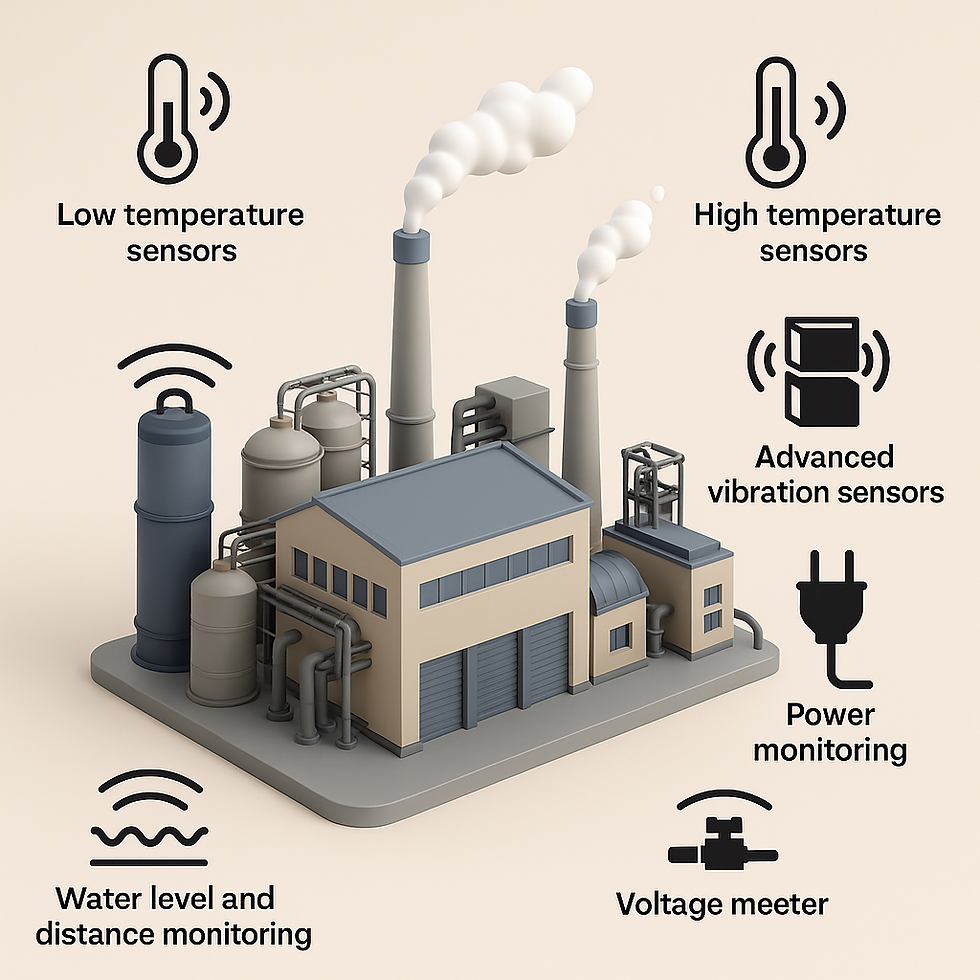

In high-stakes industrial environments, unplanned downtime, equipment failure, and inefficient maintenance can be costly. That's why leading manufacturers, processors, and energy operators are turning to wireless IoT monitoring—a smarter, faster way to stay on top of performance and prevent problems before they happen.

With Monnit’s advanced remote monitoring technology, delivered by ProSense, you can monitor key assets and environmental conditions in real time, from anywhere.

⚙️ Industrial Monitoring Made Easy

Forget the complexity of traditional SCADA retrofits or wired sensors. Monnit’s wireless platform allows easy installation, low maintenance, and scalable integration across your factory, warehouse, or processing site.

Here’s how Monnit + ProSense are helping Australian industry leaders implement smarter predictive maintenance:

🌀 Differential Air Pressure Sensors

Monitor airflow and filter performance across cleanrooms, HVAC systems, and production zones to ensure compliance and efficiency.

🌡️ High & Low Temperature Sensors

Use rugged K-type thermocouples or precision ambient sensors to track temperature in chemical processes, hot zones, or storage areas.

⚙️ Vibration Sensors

Continuously assess rotating machinery for imbalance, bearing wear, or failure signatures, before downtime strikes.

⚡ Power Monitoring (Up to 500 VAC)

Track voltage status and detect energy anomalies, enabling smarter power management across your facility.

💨 Pressure Sensors (e.g., 0–50 PSIG)

Ensure steam, gas, and fluid systems maintain safe and efficient operating ranges.

📏 Water Level & Distance Sensors

Prevent overflow, dry run, or pump failures in tanks, pits, and sumps—critical for utilities, wastewater, and process plants.

💧 Dry Contact Sensors

Integrate with floats, switches, alarms, or relays to monitor pumps, doors, generators, emergency systems, and more.

📲 All Connected Through iMonnit® Cloud Software

Every Monnit sensor feeds data to the iMonnit Cloud Platform, allowing you to:

Access live dashboards from any device

Set custom thresholds and real-time alerts via SMS/email

Log trends, reports, and insights for compliance or preventive action

Scale from one machine to hundreds across multiple sites

🔗 Fast, Secure Connectivity with ALTA IoT Gateways

No complicated networking. ALTA gateways securely connect your sensors to the cloud with long-range wireless, ideal for large or complex industrial sites.

✅ Why Industrial Sites Choose Monnit + ProSense:

No programming required

Fast wireless installation – reduce cabling, downtime, and IT dependency

Australian supply & support through ProSense

Custom kits tailored to your industry and site needs

Rugged industrial-grade enclosures and components

Whether you're managing a food plant, manufacturing facility, energy operation, or warehouse, Monnit powered by ProSense gives you reliable insights, instant alerts, and zero guesswork.

📞 Ready to Modernise Your Maintenance?

🔗 Visit: www.prosense.com.au📧 Contact: sales@prosense.com.au