Navigating Industrial Automation: Choosing Between Modular PLCs, HMI and PLC Combos, and Remote I/O Solutions

- tass peters

- Sep 30, 2025

- 4 min read

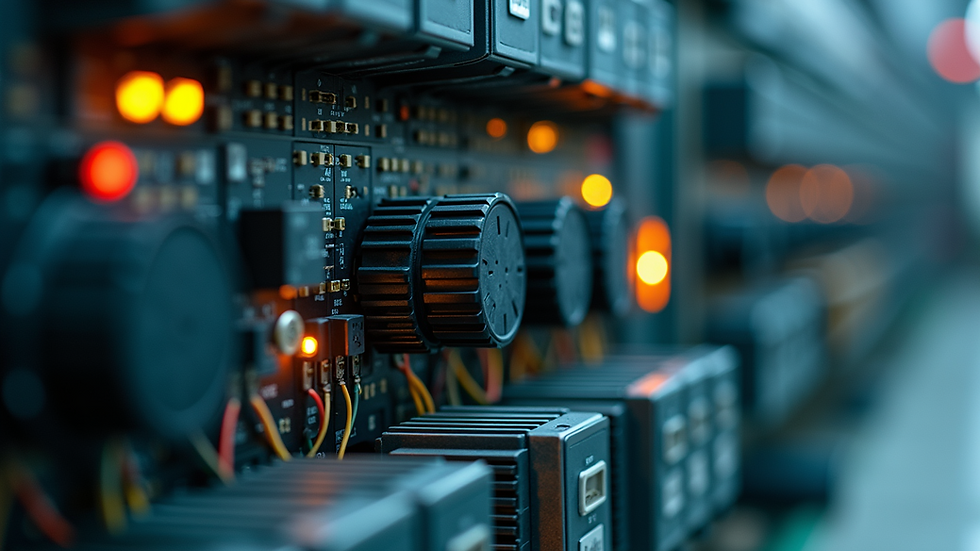

In the fast-paced world of industrial automation, selecting the right control system can significantly influence productivity, cost, and adaptability. The options available—Modular PLCs, HMI and PLC combos, and Remote I/O solutions—come with unique strengths that can meet varying business needs. Understanding these technologies is essential for making informed purchasing decisions. This post will delve into these options and illustrate how ProSense delivers cost-effective, high-quality solutions tailored to your operational requirements.

Understanding PLCs in Industrial Automation

Programmable Logic Controllers (PLCs) are essential for controlling and automating machinery and processes. They enhance operational efficiency and productivity. In fact, industries utilizing PLCs have reported improvements in process reliability by up to 30%, leading to lower operational costs.

PLCs come in various types, including Modular PLCs, HMI and PLC combos, and Remote I/O solutions. Each type serves different applications effectively based on their architecture and functionalities.

Modular PLCs: Flexibility and Scalability

Modular PLCs feature a structure that allows users to customize their systems by adding or removing components based on their operational needs. This adaptability is particularly beneficial for businesses anticipating growth or change.

Advantages of Modular PLCs

Customisation: Businesses can select modules specifically designed for their operations, ensuring optimal performance. For example, a food processing plant might opt for modules that handle high-temperature inputs.

Scalability: As production demands increase, companies can incorporate up to 50% more modules without the need to overhaul their existing infrastructure.

Maintenance: This system allows for quick replacement of faulty modules, significantly reducing downtime. Studies show that modular systems can lower maintenance downtime by 20-40%.

Ideal Applications

Modular PLCs are perfect for large operations in manufacturing, food processing, and pharmaceuticals. For instance, a large automobile manufacturer can customize their PLC to manage complex assembly lines effectively.

HMI and PLC Combos: User-Friendly Solutions

HMI and PLC combos integrate the control functions of PLCs with the simple interface of HMIs, streamlining process monitoring and control.

Advantages of HMI and PLC Combos

Ease of Use: An intuitive design caters to users with diverse skill levels, reducing training time by around 50%. For example, operators in a small batch processing operation can quickly learn to navigate the system, leading to fewer errors.

Real-Time Monitoring: Operators can see and respond to operational data as it happens, which can improve decision-making speed by 15-25% in emergency situations.

Space Efficiency: Combining these systems reduces the footprint needed for control panels, making it ideal for compact areas.

Ideal Applications

HMI and PLC combos work well for smaller setups like packaging lines, HVAC systems, and limited manufacturing operations. A craft brewery, for instance, may utilize this combo to efficiently manage their brewing process in a limited space.

Remote I/O Solutions: Expanding Reach

Remote I/O solutions enable the distribution of I/O points away from the main control unit, which is especially useful in extensive facilities where wiring can be cumbersome.

Advantages of Remote I/O Solutions

Reduced Wiring Costs: Businesses can save anywhere from 20% to 50% on wiring by placing I/O modules nearer to sensors, significantly reducing installation complexity.

Flexibility: These solutions allow easy relocation or addition of I/O modules, making it easy to adapt in dynamic environments like construction sites or mining operations.

Improved Performance: Localized processing can enhance response times by as much as 30%, critical in applications like safety systems in manufacturing.

Ideal Applications

Remote I/O solutions excel in industries such as oil and gas, water treatment, and large-scale manufacturing where high levels of equipment spread require efficient control. For example, in oil refineries, these systems can facilitate monitoring of hundreds of sensors over large areas.

Choosing the Right Solution

Selecting between Modular PLCs, HMI and PLC combos, and Remote I/O solutions involves several considerations:

Application Size: Larger facilities might gain more from Modular PLCs or Remote I/O, whereas smaller operations could opt for HMI and PLC combos.

Future Needs: If long-term growth is a concern, Modular PLCs provide the best scalability.

Budget Constraints: Cost is always an important factor. ProSense’s competitive pricing ensures you can find a suitable solution that aligns with your budget.

User Expertise: Assess the technical skills of your team. HMI and PLC combos are often easier for those with limited technical expertise to operate.

ProSense Solutions: Cost-Effective and Versatile

ProSense distinguishes itself in industrial automation by providing effective solutions tailored for diverse needs without excessive costs. Their products aim to be flexible, scalable, and simple to use, helping businesses enhance their operations efficiently.

Why Choose ProSense?

Diverse Product Range: ProSense offers Modular PLCs, HMI and PLC combos, and Remote I/O solutions, guaranteeing that businesses can find options matching their unique needs.

Cost Efficiency: Their competitive pricing structures allow high-performance solutions without the burden of high initial costs.

Expert Support: ProSense delivers robust support and resources to ensure effective implementation and maintenance of automation systems.

Simplified Guide to Industrial Automation Choices

Navigating the complexities of industrial automation does not have to be daunting. By illuminating the differences among Modular PLCs, HMI and PLC combos, and Remote I/O solutions, we simplify your decision-making process. Each option is tailored for specific applications, making them suitable for various industries.

By carefully evaluating the size of your operation, growth potential, budget, and user skill levels, you can choose a solution that boosts your operational efficiency. ProSense provides an extensive array of cost-effective solutions, ensuring that every business, whether large or small, can implement smart automation strategies. Whether you need the flexibility of Modular PLCs, the intuitiveness of HMI and PLC combos, or the reach of Remote I/O solutions, ProSense is equipped to meet your needs.